Part Number: APS66-15300

Eligibility Notice

Click here to view product eligibility.

Product Details

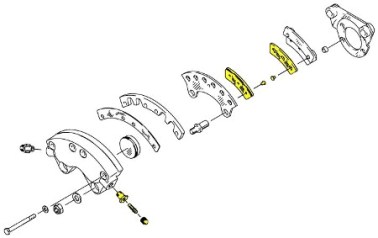

Metallic (adherent) type brake lining

Note for Cessna 208 series aircraft: APS66-03300 (Standard Lining) and APS66-15300 (Extended Life Lining) are both approved for the Cessna 208 series aircraft. Aircraft with 30-182A calipers installed must use APS66-15300 linings. Aircraft with 30-182 calipers installed may use either APS-03300 or APS66-15300 linings in complete sets. NEVER mix APS66-03300 linings on the caliper as the APS66-15300 linings. The APS66-15300 are 0.035" thicker than the APS66-03300.

Please note:

Eligibility depends on the wheel, brake, and aircraft make, model, and serial number. Please see the current catalog information or click "View Eligible Aircraft" and read any applicable comments to verify and/or determine eligibility.

APS Brake Linings

Improve braking performance

Metallic and Semi-Metallic Brake Linings

Two types of brake linings are available: semi-metallic/organic (abrasive) and metallic (adherent). The part number of the brake assembly as determined by the OEM dictates which type of lining is to be used.

The semi-metallic linings are made with Kevlar fibers integrated into the material, providing the greatest stopping power and long lining life. The optimal operating temperature of the semi-metallic linings is 600-900 deg F.

The main ingredient in the metallic linings is iron. In an adherent system, a thin layer of lining material transfers and adheres to the disc during break-in. The optimal operating temperature range of the metallic linings is 950-1200 deg F.

Brake discs, rivets and pins also sold separately. APS linings can be used with any OEM or PMA discs.

|

Warning:

|

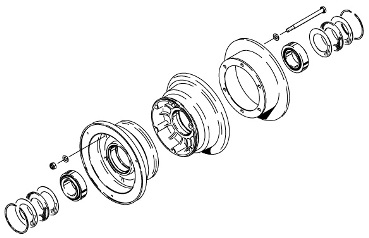

Brake bleed valves, wheel bearing cups and cones, and wheel grease seals also available.

Related Categories

Eligible Aircraft

| Make | Series | Model | Beginning S/N | Ending S/N | Eligibility Chart |

| Cessna | 208 | 208 | 20800001 | 20899999 | |

| Cessna | 208 | 208B | 208B0001 | 208B9999 | |

| Quest Aircraft | Kodiak | Kodiak 100 | 100-0001 | 100-9999 |

Related Documents

PMA Lists

| Aviation Products Systems PMA Supplement 32 |

| Aviation Products Systems PMA Supplement 34 |

Non-Reference Documents

| APS Minimum Wear Dimensions |

Installation, Use, and Maintenance Instructions

| APS Break-In Procedures |

Related Product Catalog Pages

| APS Catalog Information |

Related Items

Please verify product details for suitability for your application.

Kits That Include APS66-15300

Please verify product details for suitability for your application.

WARNING: Cancer and/or Reproductive Harm - www.P65warnings.ca.gov

WARNING: Cancer and/or Reproductive Harm - www.P65warnings.ca.gov