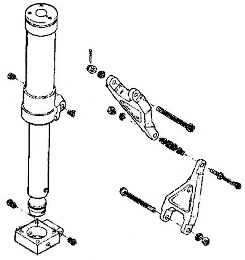

Torque Link Repair

FAQs for "Torque Link Repair"

Frequently Asked Questions

Do I need anything else besides the torque link repair kit?

You might need a few of the NAS1149F0316P ultra-thin washers to fine tune the center “knee” joint fit on most of the Cessna airplanes. They are not included in the kit.

How do you remove torque link bushings to install new ones?

Removing the flanged bushings from the torque link forging can be difficult as there is not a good surface to press against or grab onto. An easy way to remove them is to thread them with a tap, screw a bolt in the thread you made, and then drive or press against the bolt. The thread does not have to be a full depth thread for the bolt to hold securely in the bushing. The bushing material is somewhat hard, but not so hard that a standard hardware store tap will not do the job. Use cutting oil on the tap to prevent tap damage. Normally the bushing will then come out easily.

For stubborn bushings, soak the link assembly in boiling water before pressing the bushing. The heat will expand the aluminum forging more than the steel bushing. This helps loosen the press fit while limiting the temperature to prevent from overheating and harming the heat treat of the aluminum forging. A controlled oven can be substituted for boiling water as a heat source, but do not exceed 350° F. Do not use flame or other non-controlled heat sources.

An alternate method is to put dry ice in the bushing before driving or pressing on the bolt you threaded into the bushing. Do not over-press or hammer as the aluminum can gall to the bushing and leave a damaged bushing bore. If the bushing does not come out with light to moderate force take the time to use some heat or cold to help.

I installed a torque link kit and serviced my shimmy dampener; why do I still have a shimmy problem?

There are many components all connected to keep the nose gear in line. If one component is worn or out of tolerance it can cause shimmy problem. Reference Dave McFarlane’s article: Can You Stop Nose Gear Shimmy instructions and suggestions.

Overlooked items also include the rod ends, shimmy dampener mounting and attachment, shimmy dampener, and steering collar. The steering collar is where the steering rod tubes connect and the upper torque link is attached to, along with the shimmy dampener on most aircraft. If the steering collar has play vertically and laterally and is allowed to tilt; that will cause excessive wear and force on the torque links, steering, and strut components. There are three different thicknesses of shims to help get the collar in place.

Ensure that the shimmy dampener is working properly with no dead spots in dampening action. The cylinder could be worn on the inside or on a piston that warrants replacement of components. All of the nose strut components are tied to each other and any movement is transmitted through to the tire and back through the dampening system, which if remedied will continue to be more pronounced.

Is the proper nut and bolt torque important?

It is very important to maintain proper torque for the bolts that clamp the chrome bushing/spacer at the upper attachments to the steering collar and the lower attachment to the nose gear strut. It is commonly thought that the chrome bushing/spacer is kept in position by the bolt filling the center bore of the bushing/spacer. This is not correct as the inner bore of the chrome bushing/spacer and the bolt are a loose non-precision fit. The bushing/spacer is secured by the bolt end, clamping the spacer so that it is tight between the arms of the aluminum forgings. Any looseness of this end clamp will allow movement of the chrome bushing/spacer. This movement will erode the aluminum forgings and create more free motion of the torque link.

All shimming of the torque links must be done with proper torque on the bolts. Periodically and during nose gear inspections, check the torque on the upper and lower torque link bolts. If the chrome bushing/spacer is allowed to move, the resultant wear can require replacement of the expensive aluminum forgings. McFarlane is working on a repair for the worn aluminum forgings. Unlike our competitors, extra care is given to the machining of the McFarlane chrome bushing/spacers to give the largest possible bearing surface to the ends that bear against the aluminum forgings. Chamfers or bevels are kept very small.

Torque Link Repair Kits for Cessna Aircraft

Solves and prevents many wheel shimmy problems

- Expanded eligibility includes all Cessna aircraft models 150 thru 210

- Includes 177 Cardinals and many aircraft with heavy duty landing gear

- Complete FAA-PMA kits include all commonly replaced torque link parts

- Only McFarlane has shims in three thicknesses for a precision fit

- Can You Stop Nose Gear Shimmy? by Dave McFarlane

For ordering information, go to Cessna Torque Link Repair

Torque Link Repair Kits for Piper Aircraft

Prevents shimmy by removing looseness in the torque links

Prevents shimmy by removing looseness in the torque links

- Convenient kits replace all common wear torque link components

- Fits most prop driven Piper aircraft

- Contains all FAA approved parts and standard hardware

- Save time and money! No more research and ordering of individual parts

- Can You Stop Nose Gear Shimmy? by Dave McFarlane

For ordering information, go to Piper Torque Link Repair

Why choose McFarlane?

OUR PARTS ARE ENGINEERED TO LAST LONGER WHILE SOLVING KNOWN SAFETY ISSUES

OVER 40,000 PARTS IN STOCK WITH SAME DAY SHIPPING IF ORDERED BY 3PM

OUR TEAM PROVIDES THE OLD-FASHIONED CUSTOMER SERVICE THAT YOU EXPECT