Cessna Seat Rails

FAQs for "Cessna Seat Rails"

Frequently Asked Questions

Can I replace rivets with screws when replacing my seat rails?

Yes, but there are some restrictions. The screws must be structural screw with a minimum tensile strength of 50ksi. See SAIB CE-90-03R2 for more details.

Can use blind rivets (e.g., CherryMAX or CherryLOCK) when replacing my seat rails?

We do not recommend using blind rivets for seat rail installation.

What is the standard hole depth for drilling additional holes in seat rails?

Determine which extrusion is used: STE101 and STE102 - Standard hole depth drilled on the roller flange is .330” and standard diameter is .277”. STE103 and STE104 - Standard hole depth drilled on the roller flange is .280” and standard diameter is .277”.

Seat Rails for Cessna Aircraft

- Carefully engineered with many improvements

- Added strength and longer life

- Anodized for corrosion and wear resistance

- Easier installation

- Full interchangeability with the original Cessna parts

No Pre-Drilled Rivet Holes for Precise Installation

McFarlane seat rails do not have pre-drilled rivet holes in the rail base allowing the installer to exactly match the aircraft floor rivet pattern. McFarlane discovered while installing and developing our replacement seat rails that the seat rail attachment hole pattern was not consistent from aircraft to aircraft. Even small inconsistencies in the hole locations in the aircraft floor make installation of new seat rails very difficult. For this reason, McFarlane does not pre-drill rivet holes at the factory. (Existing stock may have a few pilot attachment holes drilled at the factory.) This allows the installer to precisely locate the attachment holes to match the holes in the aircraft floor. All special sized or machined attachment holes are machined to finish dimensions. It is necessary to replace all fasteners when the seat rails are installed.

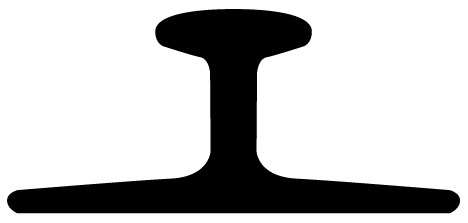

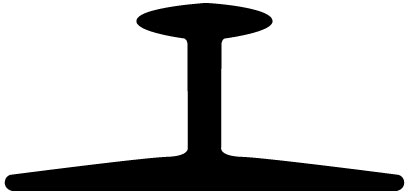

More Material in the Right Places

After studying countless worn and failed seat rails McFarlane's rails were designed with 15% more metal in critical areas. The result is more crack resistance, durability, strength and longer life.

|

|

|

|

Installation Tip: |

Why choose McFarlane?

OUR PARTS ARE ENGINEERED TO LAST LONGER WHILE SOLVING KNOWN SAFETY ISSUES

OVER 40,000 PARTS IN STOCK WITH SAME DAY SHIPPING IF ORDERED BY 3PM

OUR TEAM PROVIDES THE OLD-FASHIONED CUSTOMER SERVICE THAT YOU EXPECT