Supersedures

Related Documents

Eligible Aircraft

| Make | Series | Model | Start S/N | End S/N | Comment | Eligibility Chart |

|---|---|---|---|---|---|---|

| Beechcraft | 100 | 100 | B-2 | B-93 | ||

| Beechcraft | 100 | A100 | B-90 | B-247 | ||

| Beechcraft | 100 | B100 | BE-1 | BE-137 | ||

| Beechcraft | 200 | 200 | BB-2 | BB-912 | ||

| Beechcraft | 200 | 200C | BL-1 | BL-36 | ||

| Beechcraft | 200 | 200CT | BN-1 | BN-1 | ||

| Beechcraft | 200 | 200T | BT-1 | BT-22 | ||

| Beechcraft | 200 | A200 (C-12A) | BC-1 | BC-61 | ||

| Beechcraft | 200 | A200 (C-12A) | BD-1 | BD-9999 | ||

| Beechcraft | 200 | A200 (C-12C) | BC-62 | BC-9999 | ||

| Beechcraft | 200 | A200 (C-12C) | BD-1 | BD-30 | ||

| Beechcraft | 200 | A200CT (C-12D,C-12F,FWC-12D) | BP-1 | BP-63 | ||

| Beechcraft | 200 | A200CT (RC-12D,RC-12H) | GR-1 | GR-19 | ||

| Beechcraft | 200 | A200CT (RC-12G) | FC-1 | FC-9999 | ||

| Beechcraft | 200 | A200CT (RC-12K) | FE-1 | FE-9 | ||

| Beechcraft | 200 | A200CT (RC-12N) | FE-10 | FE-24 | ||

| Beechcraft | 200 | A200CT (RC-12P) | FE-25 | FE-35 | ||

| Beechcraft | 200 | A200CT (RC-12Q) | FE-32 | FE-36 | ||

| Beechcraft | 200 | A200C (UC-12B) | BJ-1 | BJ-9999 | ||

| Beechcraft | 200 | B200 | BB-734 | BB-9999 | ||

| Beechcraft | 200 | B200C (C-12F) | BL-37 | BL-9999 | ||

| Beechcraft | 200 | B200C (C-12R) | BP-64 | BP-9999 | ||

| Beechcraft | 200 | B200CGT | BZ-1 | BZ-9999 | With STC SA646GL, SA650GL or SA890GL installed | |

| Beechcraft | 200 | B200CT | BN-2 | BN-4 | ||

| Beechcraft | 200 | B200C (UC-12F) | BU-1 | BU-10 | ||

| Beechcraft | 200 | B200C (UC-12M) | BV-1 | BV-10 | ||

| Beechcraft | 200 | B200GT | BY-1 | BY-9999 | ||

| Beechcraft | 200 | B200T | BT-23 | BT-9999 | ||

| Beechcraft | 90 | F90 | LA-2 | LA-204 | ||

| Beechcraft | 90 | F90-1 | LA-202 | LA-236 | ||

| Beechcraft | 99 | 99 | U-1 | U-136 | ||

| Beechcraft | 99 | 99A | U-36 | U-147 | ||

| Beechcraft | 99 | A99 | U-1 | U-147 | ||

| Beechcraft | 99 | A99A | U-132 | U-132 | ||

| Beechcraft | 99 | B99 | U-146 | U-164 | ||

| Beechcraft | 99 | C99 | U-165 | U-239 |

Related Categories

Product Details

Please note:

Eligibility depends on the wheel, brake, and aircraft make, model, and serial number. Please see the current catalog information or click "View Eligible Aircraft" and read any applicable comments to verify and/or determine eligibility.

APS Brake Linings

Improve braking performance

Metallic and Semi-Metallic Brake Linings

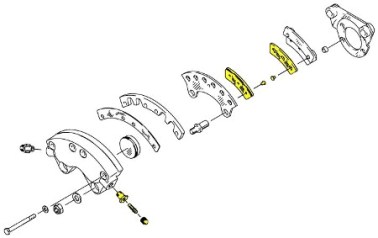

Two types of brake linings are available: semi-metallic/organic (abrasive) and metallic (adherent). The part number of the brake assembly as determined by the OEM dictates which type of lining is to be used.

The semi-metallic linings are made with Kevlar fibers integrated into the material, providing the greatest stopping power and long lining life. The optimal operating temperature of the semi-metallic linings is 600-900 deg F.

The main ingredient in the metallic linings is iron. In an adherent system, a thin layer of lining material transfers and adheres to the disc during break-in. The optimal operating temperature range of the metallic linings is 950-1200 deg F.

Brake discs, rivets and pins also sold separately. APS linings can be used with any OEM or PMA discs.

|

Warning: |

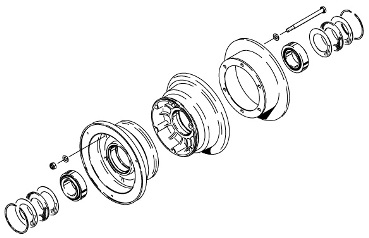

Brake bleed valves, wheel bearing cups and cones, and wheel grease seals also available.

Recommended Categories

Why choose McFarlane?

OUR PARTS ARE ENGINEERED TO LAST LONGER WHILE SOLVING KNOWN SAFETY ISSUES

OVER 40,000 PARTS IN STOCK WITH SAME DAY SHIPPING IF ORDERED BY 3PM

OUR TEAM PROVIDES THE OLD-FASHIONED CUSTOMER SERVICE THAT YOU EXPECT

Don't see what you're looking for?

View our search tips page, support page or please contact us.

Or, try our chat feature, located on the right side of our website during business hours. We welcome your comments and suggestions.

Select a Category