Improved Cessna 170/190/195 Elevator Trim Skins

Minor change results in major improvement!

The outboard tip of the elevator trim skins for the Cessna 170, 190 and 195 has always been an area prone to cracking. This is because the original skins had a formed corrugation at the tip that had to be "unformed" or flattened either at the factory or in the field before it could be securely riveted in place.

The process of forming that corrugation and then flattening it again work hardens the material, making it brittle and prone to cracking around the rivet. McFarlane has solved this problem. Our precision hydraulic forming process allows us to skip the final corrugation in the skin, leaving the problem tip unformed and ready to rivet. This is in contrast to Cessna's rotary forming process, which does not allow the option to skip a corrugation.

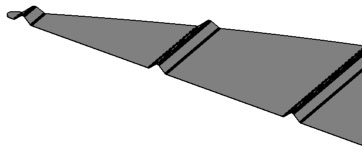

Original design:

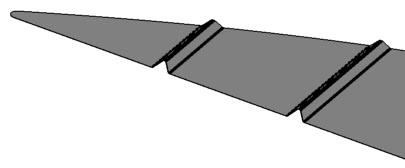

Improved design:

- More precise corrugation spacing and shape

- No pre-drilled holes to misalign

- Precisely formed and CNC cut to shape to match OEM skins

- Plastic coated on both sides for better protection during handling (remove before installation)

- Direct replacement - No STC required

- Available as convenient kits or individually

For ordering information, go to Elevator Trim Skins.