Baffle Seal Material

FAQs for "Baffle Seal Material"

Frequently Asked Questions

How do I repair a damaged cowl before installing Cowl Saver?

There are several ways of repairing worn cowl surfaces. Epoxy fill is sometimes used for minor wear, or flush or double flush riveted aluminum doubler plates can be formed and installed over the damage. McFarlane has a high temperature (400deg F) sandable two part epoxy with an aluminum filler that works well for filling minor cowl skin defects; please see P/N 20 GLUE KIT. Consult with your A&P mechanic for the best repair solution for your aircraft.

How much Cowl Saver material goes above and below the rivets?

There is not a concrete answer that will work for every customer; it really depends on each individual installation. As a general rule, as long as you do not put the rivets at the very edge of the material it will not rip out. If you use McFarlane’s retainer strips, they can line up the edge of the material with the bottom of the retainer strip and then put the rivets in the middle of the strip.

Bi-Flex Cowl Saver can be adjusted for maximum stiffness across the gap between the engine baffling and the cowl. If you have a large gap, you will want to extend the un-scored portion out closer to the cowl so that the stiff un-scored part of the Bi-Flex Cowl Saver is bridging the gap. The stiff un-scored material will prevent air pressure from blowing the Cowl Saver out of position. If the gap is small between the engine baffling and the cowl surface, reduce the amount of un-scored Bi-Flex Cowl Saver extended across the gap. This will give you maximum flexibility for the best possible seal. After adjusting the Bi-Flex Cowl Saver position for the right amount of un-scored material in the gap, trim away any material extending more than 1/8 inch from under the retainer strips.

I have a Cessna 182R with an O-470. My baffle seals do not mount on the metal shielding around the engine, rather it actually mounts in the cowling. Can I install this material?

As long as the non-friction side is mounted towards the surface that the cowl moves against, it should be fine. However, refer to the question regarding FAA-PMA approval.

I have a Cessna 185 with an IO-520-D, can I install this material?

The Cowl Saver material drastically reduces the engine vibration that is transferred from the engine to the cowl and airframe. This is especially noticeable on the Cessna 185 aircraft with the large IO-520 engines. However, refer to the question regarding FAA-PMA approval.

Is Cowl Saver baffle seal material FAA-PMA approved or have an STC?

It is certified to meet AMS3320G, which is the same industry standard specification to which other fiberglass reinforced silicone baffle seal material is certified, however it is not an STC or FAA-PMA product. It is ultimately the installing mechanics responsibility to determine whether the material is appropriate to repair the baffle seals on a specific aircraft.

McFarlane does have FAA approved die cut baffle seal kits for the re-start Cessna 172 aircraft; please see P/N BSC-KT-1. We developed this first because our patented material solves the firewall crack and other baffle seal related problems on these airplanes. McFarlane will develop more FAA approved baffle seal kits as engineering time permits.

My baffle seals attach to the cowl instead of the engine baffles. Can I use Cowl Saver?

Yes. Just ensure that the low friction side is in contact with the engine baffles.

My cowl seal material keeps blowing past the engine baffling creating a big air leak. Will Cowl Saver prevent this?

Yes. Cowl Saver is stiffer than most cowl seal material in the un-scored condition. Bi-Flex Cowl Saver can be adjusted to better bridge the gap between the engine baffling and cowl surface. See the question “How much Cowl Saver material goes above and below the rivets?” for more details.

Should I buy a 3" roll or a flat sheet of Cowl Saver baffle seal material?

McFarlane recommends the Bi-Flex laser scored Cowl Saver baffle seal material for aircraft that have fairly straight baffling and cowl lines. There is no strip baffling material that works well for sealing a curved cowling. You can cut wedges out in the strip and stretch the outer edges or overlap it, but the best fit for a curved baffling is to cut a curved piece out of a flat sheet. Many customers order both the Bi-Flex roll and a flat sheet to give the best and easiest installation possible. You will then have enough material to do several airplanes.

Please also read Customized Flexibility for Optimal Cooling.

Soft rivets are too hard on my hands to install, can you offer an installation tip?

Use of a deep throated hand squeezer will make installation using one hand easier. Always adjust the rivet squeezer for the right rivet height when the squeezer is closed all the way. This gives you maximum squeezer leverage and ease of use.

What is Bi-Flex and will it cost more than standard baffle seal material?

McFarlane manufactures a patented, Teflon-bonded, reinforced silicone rubber baffle seal material that gives you 30 times less friction on one side. Bi-Flex is our trade name for the laser scoring of this material to give maximum flexibility only where it is needed. For more information, please read Customized Flexibility for Optimal Cooling.

Yes, Bi-Flex costs 25% to 50% more for the extra processing and it will take a little longer to install, but this cost is small compared to the cost of cowling repairs and other damage from the engine movement that is transferred into the cowling and airframe. You will see a drastic reduction in cowling wear, cracks, and fastener fretting. You will also see a lot less cracking and damage to the metal engine baffles.

Which side of Cowl Saver goes against the cowl?

The slick side. Rub against a metal or glass surface to tell the difference. For Cowl Saver that is black on one side and grey on the other, the black side goes against the cowl.

Why don’t we use pop rivets in P/N RIVET-KIT-2 instead of soft rivets?

Following guidelines from a previous Service Bulletin by Cessna, McFarlane chose to use soft rivets. The use of pop rivets might be considered a minor alteration by some mechanics.

Why should I purchase the Cowl Saver Scoring Tool, P/N TOOL120, if the Cowl Saver material is already scored?

McFarlane uses a laser to score the Bi-Flex Cowl Saver material to approximately 40% of the strip width. This works well for assuring a great air seal when you have straight or minor cowl shape changes. However, where you have a curved baffle and cowl, you will get a better fit by cutting out curved pieces of Cowl Saver from a flat sheet and then custom scoring the Teflon on the outer edges for the flexibility you need. You can score Cowl Saver with a sharp razor blade or knife. The TOOL120 scoring tool makes several scores at once and is designed to prevent cutting too deep and damaging the fiberglass reinforcing in the center of the material. The job will go much faster with use of the tool. Even with the pre-scored Bi-Flex, you may find situations where some additional flexibility by custom scoring is helpful for the best possible fit. For more information, please read Customized Flexibility for Optimal Cooling.

30x less friction than any other baffle seal on earth!

Reduce airframe vibration, stop cowl and firewall cracks

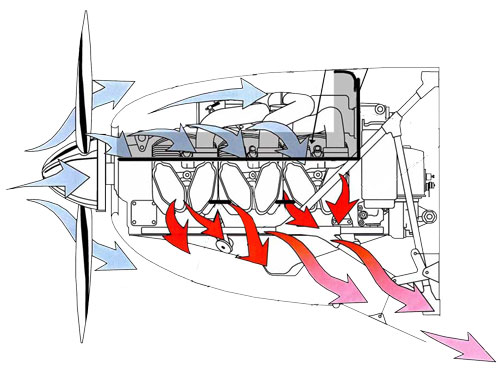

Baffle seal friction causes airframe vibration and destroys cowls

Typical silicone rubber baffle seals have a coefficient of friction among the highest of any known material. This friction transfers engine vibration into your cowl and firewall causing

fastener fretting, fatigue, cracking, chafing and airframe vibration.

Cowl Saver™ has 30 times less friction!

- Dramatically reduces the friction between your cowl and baffle seals

- One side is silicone and the other is a low friction Teflon coated rubber

- Half of the engine vibration you feel in the cockpit is from baffle seal transfer

Low friction saves you money!

- Reduces transfer of vibration to the engine cowl and airframe

- Eliminates cowl erosion

- Extends baffle seal life

- Reduces expensive cowl and cowl fastener repairs

- Reduces fatigue and cracking in baffles, cowl skins and firewall

- Cowling even goes on easier!

- 36-month Money Back Guarantee!

Unbeatable performance

- Promotes superior engine cooling

- Ideal balance of flexibility and stiffness

- Fiberglass reinforced

- Meets industry standard AMS3320G

- Use scoring tool P/N TOOL120 for customized flexibility

Bi-Flex™ Technology

Precision laser engraved flex pattern ensures optimum flexibility/stiffness combination for maximum cooling and minimum friction.

For more information, please read Customized Flexibility for Optimal Cooling.

| P/N | Size |

| CS085X18X36G | 18 in X 36 in |

| CS085X36X36G | 36 in X 36 in |

| CS085X3X36GBF | 3 in X 36 in with Bi-Flex™ |

| CS085X3X108GBF | 3 in X 108 in with Bi-Flex™ |

| CS085X3X156GBF | 3 in X 156 in with Bi-Flex™ |

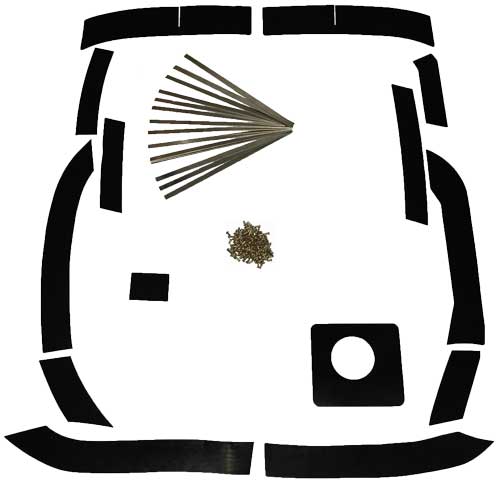

| Color: Black/Gray Thickness: 0.085 inches Convenient Baffle Seal Repair Kits also available. |

|

|

Note: For proper function, install Cowl Saver™ material so that only the low friction (black) side touches the cowl's inside surface. Carefully plan the baffle seal installation before cutting the material. |

- Unbeatable performance – ideal balance of flexibility and stiffness

- 30x less friction – eliminating cowl erosion

- Reduce fatigue and expensive baffle, cowl and firewall repairs

- Eliminate guess work! Kits include all required baffle seals, soft rivets, and McFarlane P/N 6036-012 retainer strips

-

Cut to fit, saving you time and money

-

Individual baffles available for sale

Precision laser engraved flex pattern ensures optimum flexibility/stiffness combination for maximum cooling and minimum friction. For more information, please read Customized Flexibility for Optimal Cooling.

For more information visit Baffle Seal Kits.

Baffle seals created using this product are protected by U.S. Patent No. US 8,070,099 B2.

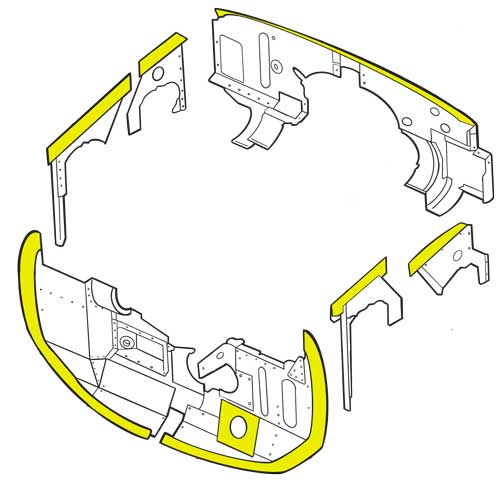

Complete Engine Baffles for Cessna, Piper, Beechcraft, Mooney, and Grumman also available.

Why choose McFarlane?

OUR PARTS ARE ENGINEERED TO LAST LONGER WHILE SOLVING KNOWN SAFETY ISSUES

OVER 40,000 PARTS IN STOCK WITH SAME DAY SHIPPING IF ORDERED BY 3PM

OUR TEAM PROVIDES THE OLD-FASHIONED CUSTOMER SERVICE THAT YOU EXPECT

Select a Category